КАТЕГОРІЇ

Адреса виробничих потужностей

Україна Черкаська область м. Черкаси

проспект Хіміків 74 Д

проспект Хіміків 74 Д

ПРОЕКТУВАННЯ ТА РОЗРОБКА

ВИРОБНИК Обладнання УКРАЇНА

КАТЕГОРІЇ

ПРО НАС

КОМПЛЕКТАЦІЯ ЖНИВАРКИ

• призначена для збирання соняшнику рядного та суцільного посіву

• проста конструкція приводу

ЗАПЧАСТИНИ

Запасні частини жниварки для збирання соняшника

НАДАННЯ ПОСЛУГ З ОБРОБКИ МЕТАЛА

Лазерне різання металу,

Гнуття,

Зварювання

ЦАПФА ПРАВА ЦП 170.202

Сегмент БРПК

ФЛАНЕЦЬ ЗІ СТУПИЦЕЮ ФС 170-63,5

Жниварка для збирання соняшника 6м

Жниварка для збирання соняшника 7,4м

Жниварка для збирання соняшника 9,1м

ЖНИВАРКА ДЛЯ ЗБИРАННЯ КУКУРУЗИ

Млин молотковий

Змішувач шнековий SMS

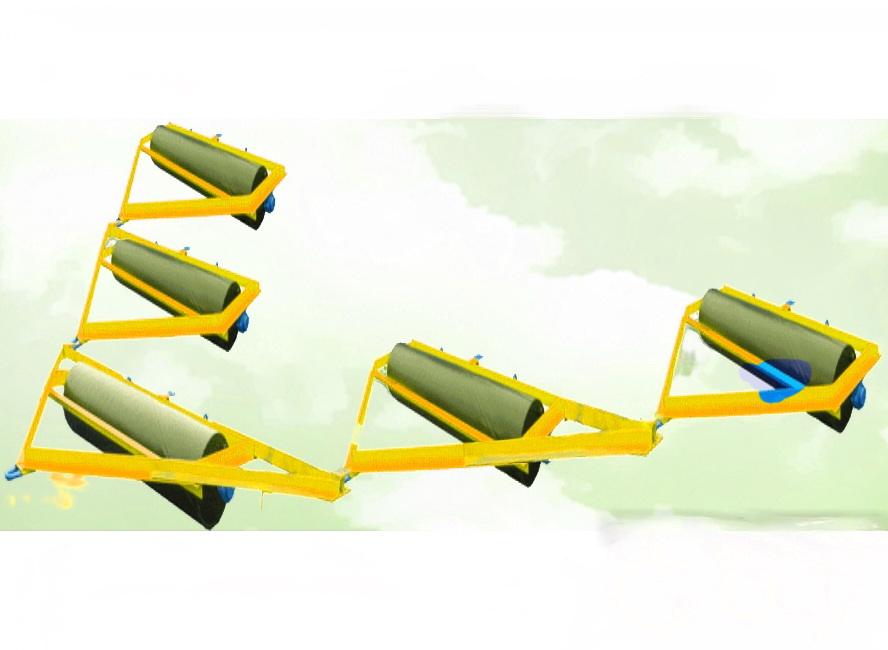

Жниварка валкова насічна

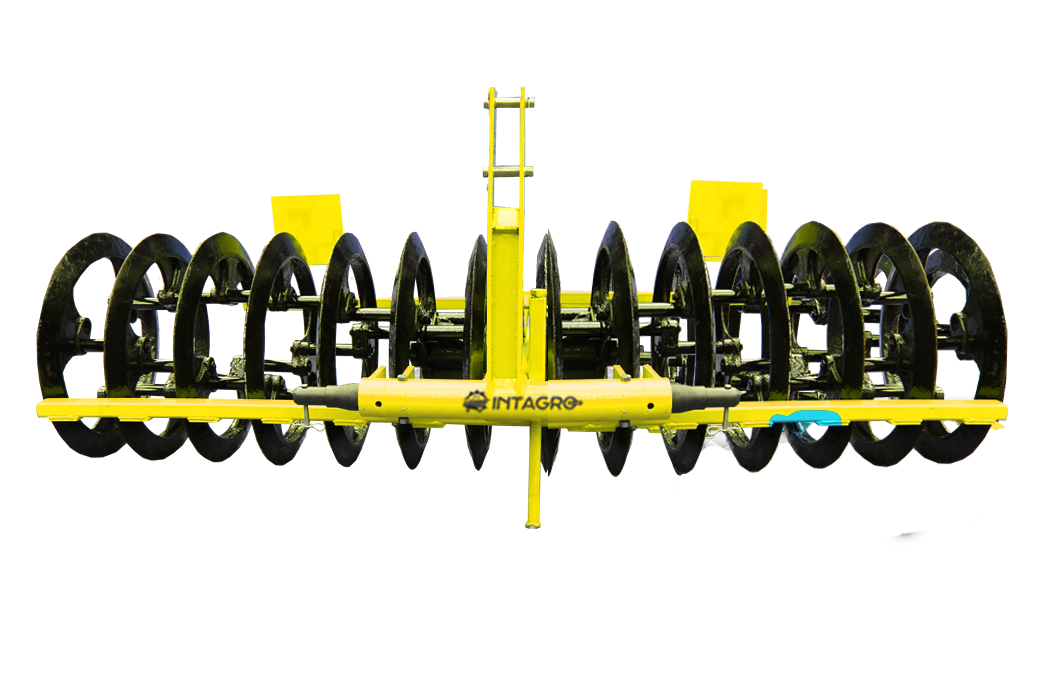

Каток кільчато-шпоровий

Каток зубчасто-кільчатий

Каток-подрібнювач (з прямим та шаховим розташуванням ножів)

Напівавтомат PDP-K для фасування в дой-пак пакети

№:

Сушарка для волоського горіха і фундука в шкаралупі (4 тонни/доба)

№:

Сушарка для волоського горіха і фундука з твердопаливним котлом

№:

Мийка для горіха, овочів, фруктів

№:

Очищувач волоського горіха від зеленої шкірки (300 кг/год)

№:

Очищувач волоського горіха від зеленої шкірки (100 кг/год)

№:

Роторний калібратор для фундука (2 фракції)

№:

Аспіраційна колона для сортування порожніх горіхів у шкаралупі

№:

Аспіраційна колона з віброподачею для волоського горіха (300 кг/год)

№:

Вібробункер (віброподача)

№:

Вібросито з аспірацією для сортування волоського горіха (500 кг/год)

№:

Вібросито для сортування ядра волоського горіха (1000 кг/год)

№:

Вібросито з аспірацією для сортування волоського горіха (300 кг/год)

№:

Аспіраційна колона з віброподачею для волоського горіха (100 кг/год)

№:

Вібросито з аспірацією для сортування волоського горіха (200 кг/год)

№:

Вібросито для сортування ядра волоського горіха (200 кг/год)

№:

Роторний калібратор волоського горіха (4 фракції)

№:

Стіл для перебирання волоського горіха

№:

Лінійний калібратор для горіха

№:

Млин молотковий

№:

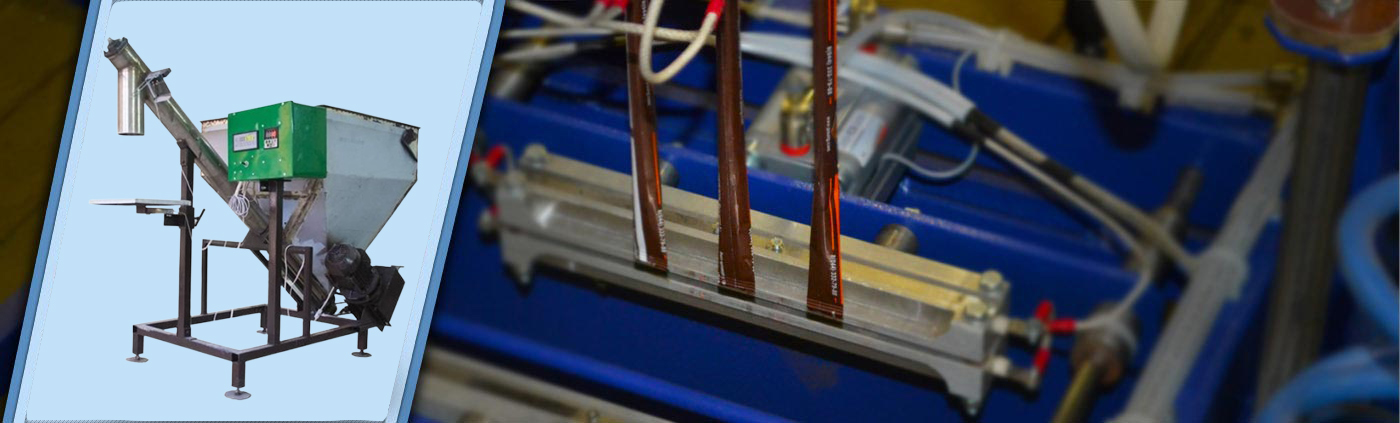

Шнековий дозатор у готовий пакет

№:

Просіювач SHP для борошна, цукру, сухого молока

№:

Змішувач із шнековим дозатором у мішок, пакет

№:

Змішувач для внесення смакових добавок BL-130; BL-360

№:

Змішувач лопатевий з нагріванням

№:

Комплекс для автоматичного зважування, дозування та змішування сипких компонентів

№:

Двохвимірний змішувач SMS

№:

Змішувач BSMS біконічний для чаю, пластівців, мюслей

№:

Змішувач сушарка

№:

Змішувач SMS для преміксів

№:

Змішувач шнековий SMS

№:

Змішувач для сипучих продуктів SPB-1

№:

Охолоджувач-очисник ОП-1

№:

Піч жаркова газ PG-1G

№:

Піч обсмажувальна електро PG-1E

№:

Піч обсмажувальна електрична прохідного типу PGP-70/PGP-70-Н

№:

Охолоджувач-очисник прохідного типу OOP-120/ООР-120-Н

№:

Дестонер

№:

Ростери для кави промислові (R-2, R-5, R-12, R-25)

№:

Піч жаркова барабанна

№:

Дозатор ваговий шнековий H-1

№:

Дозатор ваговий VD-1G

№:

Дозатор стрічковий VD-1(L)

№:

Дозатор каскадний VD-1/2

№:

Дозатор VD-1(M)

№:

Ремкомплект для очищувача горіха від зеленої шкірки (100 кг)

№:

Промислова мийка для очищення горіха від зеленої шкірки (700 кг/год)

№:

Сушарка для волоського горіха і фундука в шкаралупі (2 тонни/доба)

№:

Сушарка для горіха та фундука (до 1 т/добу)

№:

Очищувач мигдалю та волоського горіха від зеленої шкірки (200 кг/год)

№:

Очищувач фундука від плюски

№:

Очищувач волоського горіха від зеленої шкірки (300 кг/год) зі столом та регулюванням швидкості

№:

ФАСУВАЛЬНО-ПАКУВАЛЬНИЙ НАПІВАВТОМАТ З ВАГОВИМ ДОЗАТОРОМ PIN-20-V1

№:

ФАCУВАЛЬНО – ПАКУВАЛЬНИЙ АВТОМАТ З ВАГОВИМ ДОЗАТОРОМ IN-8-V

№:

Фасувальний автомат в стік пакети INSTIK-150-G2 (рідкі, густі, пастоподібні)

№:

Машина MUSH-1 для виготовлення муштуків (для кальяну)

№:

Установка NAB-1S для набивання сигаретних гільз тютюном

№:

Фасувальний автомат в стік пакети INSTIK-150-OM

№:

Дозатор ваговий шнековий H-1

№:

Піч газова для смаження насіння та горішків PG-1G

№:

Піч єлектрична для смаження насіння та горішків PG-1E

№:

Пристрій для збирання ріпаку IN-RIPAK 5.0/6.0/6.1/6.3/6.6/6.7/7.0/7.2/7,6/9.0/9,1м

№:

Платформа підбирач PP-3-4

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-KP-9-2P-01

№:

КОТОК КІЛЬЧАТО-ШПОРОВИЙ CAT СН-6U-02

№:

КАТОК КІЛЬКО-ШПОРОВИЙ CAT-CH-6U-01

№:

КАТОК КІЛЬКО-ШПОРОВИЙ CAT-CH-6U

№:

КАТОК КIЛЬЧАТО-ШПОРОВИЙ CAT-CH-10PM-02

№:

КАТОК КІЛЬЧАТО-ШПОРОВИЙ CAT-CH-10PM-01

№:

КОТОК КІЛЬЧАТО-ШПОРОВИЙ CAT CH-10PM

№:

КАТОК КІЛЬЧАТО-ШПОРОВИЙ CAT-CH-6PM-02

№:

КАТОК КІЛЬЧАТО-ШПОРОВИЙ CAT-CH-6PM-01

№:

КАТОК КІЛЬЧАТО-ШПОРОВИЙ CAT-CH-6PM

№:

КОТОК КІЛЬЧАТО-ШПОРОВИЙ CAT CH-10G

№:

КОТОК КІЛЬЧАТО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ СAT СH-9-2G-02

№:

КАТОК КІЛЬКО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-CH-ORLYK-6-02

№:

КАТОК КІЛЬКО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-CH-OR-6

№:

КАТОК КІЛЬКО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-CH-2KKSH-10G

№:

КАТОК КІЛЬКО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-CH-6G

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНІЙ ГІДРОФІКОВАНИЙ CAT-IZM-9-2P

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-12-5P-01

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-10P-01

№:

КАТОК-ПОМІЛЬНИК РІЖЧИЙ ВОДОНАЛИВНІЙ ГІДРОФІКОВАНИЙ CAT-G5-9-2P-01

№:

КАТОК ГЛАДКО-ВОДОНАЛИВНИЙ CAT-GV-10U

№:

КАТОК ГЛАДКО-ВОДОНАЛИВНИЙ CAT-GV-P-6U

№:

КАТОК ГЛАДКО-ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-GV-9-2G

№:

КАТОК ГЛАДКО-ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-GV-6G

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ CAT-ZC-6-7PM

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ CAT-ZC-2-8PM

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ CAT-ZC-6P-02

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-6P-01

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-6P

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-OR-6А

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-OR-6-02

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-OR-6

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-OL-6

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-OL-6А

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТАИЙ ГІДРОФІКОВАНИЙ CAT-ZC-GO-6

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-12-5PT

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-12-5P-02

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-12-5P

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ CAT-ZC-10P-02

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-10P-01

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-10P

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC- 9-2P-01

№:

КАТОК ЗУБЧАТО-КІЛЬЧАТИЙ ГІДРОФІКОВАНИЙ CAT-ZC-9-2P

№:

КАТОК ЗУБЧАТО-КОЛЬЧАТЫЙ CAT-ZK-2-8PM

№:

КАТОК ЗУБЧАТО-КОЛЬЧАТИЙ CAT-ZC-GO-4-5

№:

КАТОК ЗУБЧАТО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-ZH-9-2G

№:

КАТОК ЗУБЧАТО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-ZH-6G-01

№:

КАТОК ЗУБЧАТО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-ZH-6G

№:

КАТОК ЗУБЧАТО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-ZH 9-2G-01

№:

КАТОК КІЛЬКО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-CH-6G-02

№:

КАТОК КІЛЬКО-ШПОРОВИЙ ГІДРОФІКОВАНИЙ CAT-CH-6G-01

№:

КАТОК однорядний ущільнювач CAT-UP-K1U

№:

КАТОК ДВОХРЯДНИЙ Ущільнювальний CAT-UP-4-0

№:

КАТОК ДВОХРЯДНИЙ Ущільнювальний CAT-UP-2-4

№:

КАТОК ДВОХРЯДНИЙ Ущільнювальний CAT-UP-3-2

№:

КАТОК ДВОХРЯДНИЙ Ущільнювальний CAT-UP-2-8

№:

КАТОК ДВОХРЯДНИЙ Ущільнювальний CAT-UP-2-0

№:

КАТОК ДВОХРЯДНИЙ Ущільнювальний KAT-UP-1-6

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-T-6P

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-6P

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-6P

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-6R

№:

КАТОК-ПОДРІБНЮВАЧ РІЖУЧИЙ ВОДОНАЛИВНИЙ ГІДРОФІКОВАНИЙ CAT-IZM-3-2М-01

№:

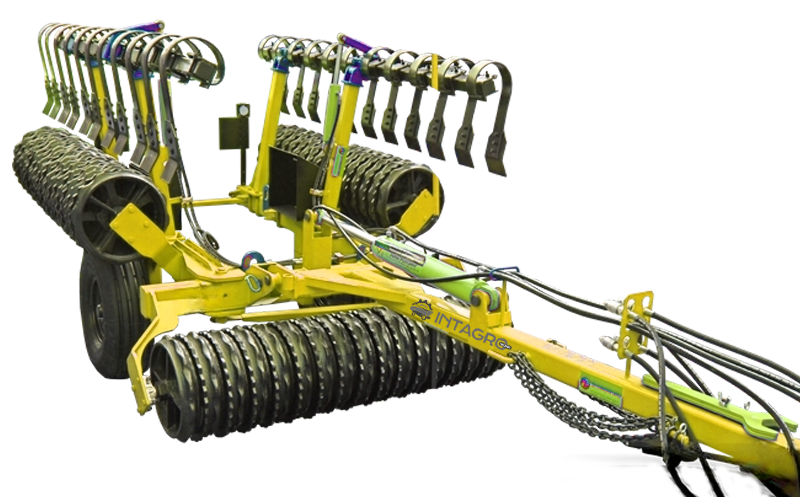

КАТОК-КУЛЬТИВАТОР КОМПАКТОР ГІДРОФІКОВАНИЙ CAT-CC-9-3

№:

КАТОК-КУЛЬТИВАТОР КОМПАКТОР ГІДРОФІКОВАНИЙ CAT-CC-6

№:

КАТОК-КУЛЬТИВАТОР КОМПАКТОР ГІДРОФІКОВАНИЙ CAT-CC4

№:

Візок універсальний

№:

Каток-подрібнювач (з прямим та шаховим розташуванням ножів)

№:

Каток зубчасто-кільчатий

№:

Каток кільчато-шпоровий

№:

Жниварка валкова насічна

№:

Фронтальний навантажувач

№:

ЖНИВАРКА ДЛЯ ЗБИРАННЯ КУКУРУЗИ

№:

Жниварка для збирання соняшника 9,1м

№:

Жниварка для збирання соняшника 7,4м

№:

Жниварка для збирання соняшника 6м

№:

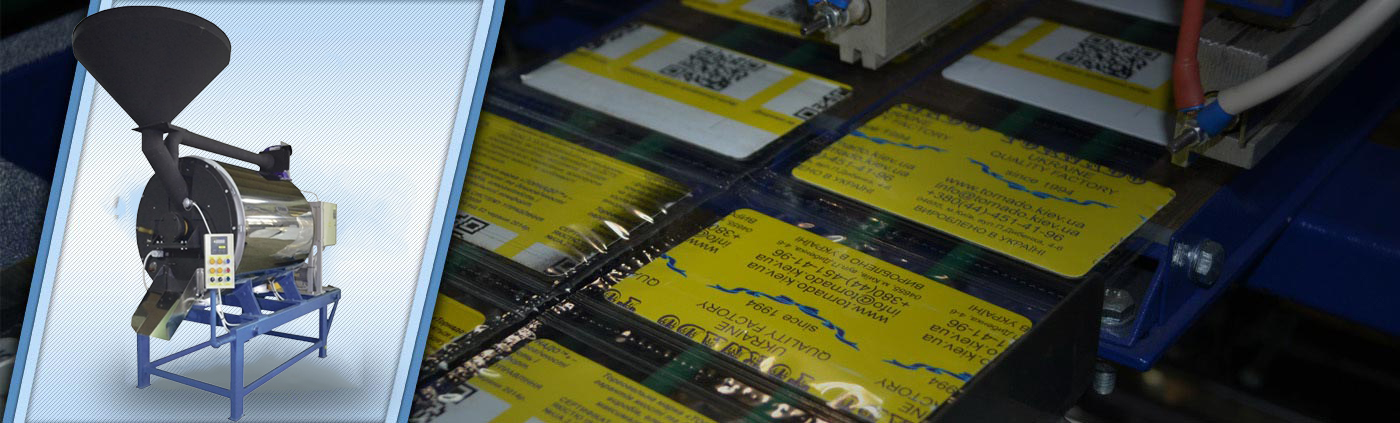

Лазерне різання металу

Машина термічного різання металу потужністю 1,5 кВт. Габарити робочого поля 3000х1500мм. Максимальна товщина листового металу 16мм. Точність позиціонування до 0,01мм. Різання може проводитись киснем, азотом та стисненим повітрям.

Додаткові можливості

- різання труб квадратних та круглих

- перфорація листового металу

- маркування та гравірування

Гнуття

Листогиб з ЧПУ з максимальним зусиллям 63 тони. Максимальна товщина 6мм. Максимальна довжина деталі 2500мм. Великий діапазон варіантів гнуття (радіусне, одно-кутове, багато-кутове тощо).

Зварювання

Апаратами напівавтоматичного зварювання MIG/MAG/FCAW/MMA 323. Завдяки високому контролю на виробництві, гарантуємо виконання робіт в максимально короткі терміни та високої якості.

Також наша компанія надає послуги з інженерно-технічної підтримки наших клієнтів на базі власного конструкторського бюро.

СЕРВІС І ГАРАНТІЯ

Ми надаємо сервісне обслуговування.

Використовуємо оригінальні запчастини та витратні матеріали для соняшникових жниварок.

Види ремонтних робіт:

– дефектовка (виявлення несправностей) жниварки

– повна або часткова заміна днища жниварки

Кожна непрацююча жниварка INTAGRO, яку ми беремо на ремонт, повністю ремонтується в нашій власній майстерні. Спочатку жниварки піддаються ретельному очищенню і дефектовці. Потім компоненти приводу і підшипники перевіряються на предмет їх працездатності, жниварка коректно налаштовується і замінюються всі зношені деталі. Готові вироби фарбуються.

Ми впевнені, що продуктивність відремонтованих жниварок не поступається новим жниваркам. За допомогою ремонту можна відновити ресурс жниварок до 95%. Фахівці сервісної та ремонтної служб INTAGRO мають необхідну кваліфікацію. Вартість та терміни виконання ремонтних робіт обумовлюються заздалегідь.

Постійно в наявності на складі оригінальні запчастини:

втулки, зірочки, ланцюги, ножі, сальники, шестерні, шайби, вали, пластини, кільця, шпонки, кришки гайки ножа та ін.

Для того, щоб дізнатися, яка саме деталь необхідна при тій чи іншій поломці, а також вартість ремонтних робіт – звертайтесь до професіоналів.

Звертайтеся до нас і ми надамо професійну консультацію.

ПРО КОМПАНІЮ

INTAGRO є новоствореним машинобудівним підприємством. Розміщення виробничих потужностей в м.Черкаси, Україна.

Основний напрямок діяльності – це виробництво машин і устаткування для сільського господарства.

контакти

Адреса виробничих потужностей

Україна Черкаська область м. Черкаси

проспект Хіміків 74 Д

проспект Хіміків 74 Д

тел. +380689027878

Відділ з продажу

Володимир Мішакін

Мобільний телефон:

Email:

Відділ постачання

Володимир Марченко

Мобільний телефон:

Email: